Introduction: The “Gummy” Nightmare of Austenitic Steel

In the world of CNC machining, few materials cause as much frustration as the 300-series Stainless Steels (304, 316, 316L). Unlike carbon steel which breaks chips cleanly, or aluminum which cuts like butter, stainless steel is notoriously ‘gummy’. But the real enemy in turning stainless steel is invisible: Work Hardening.

Austenitic stainless steels have high ductility and low thermal conductivity. When cut, the heat generated doesn’t evacuate into the chips—it stays in the cutting edge and the workpiece. Furthermore, the material’s crystal structure deforms under pressure, creating a skin that can be twice as hard as the base material. If your tool rubs against this skin, failure is instantaneous.

At Premitools, we specialize in solving these specific metallurgical challenges. Whether you are producing food-grade fittings or aerospace components, these 5 strategies will help you master the art of turning stainless steel. Explore our dedicated stainless steel turning grades.

Tip 1: The “Depth of Cut” Strategy (Don’t Rub!)

The golden rule of machining stainless is: **Cut, don’t plow.

Understanding the Hardened Zone

Every pass creates a microscopic layer of work-hardened material on the surface of the part. If your next pass has a Depth of Cut (DOC) that is shallower than this hardened layer (typically 0.05mm – 0.1mm), your insert is cutting purely through hardened steel. This causes rapid flank wear and catastrophic notch wear.

The Solution

Always ensure your DOC is significantly deeper than the potential hardened skin. For finishing passes, avoid taking ‘dust cuts’ (e.g., 0.02mm). A minimum DOC of 0.15mm is recommended to get the cutting edge under the skin and into the softer base metal.

Tip 2: Grade Selection – PVD vs. CVD

Choosing the right carbide grade is critical. While CVD (Chemical Vapor Deposition) grades are excellent for cast iron, they are often the wrong choice for stainless steel machining.

Why PVD Wins

CVD coatings are thick (10-20 microns). While heat-resistant, this thickness rounds the cutting edge. In stainless steel, a dull edge generates excess heat, accelerating work hardening.

PVD (Physical Vapor Deposition) coatings are thin (2-4 microns) and adhere tightly to the substrate. This allows for a sharper cutting edge. A sharp edge shears the material cleanly, generating less heat and reducing cutting forces. We recommend our TiAlN (Titanium Aluminum Nitride)PVD grades for 304 and 316 stainless.

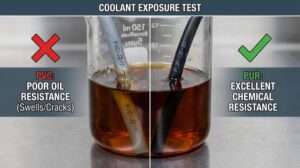

Tip 3: Coolant Strategy – Pressure Matters

Stainless steel has poor thermal conductivity. The heat stays concentrated at the tool tip.

Thermal Shock Risk

Interrupted coolant flow causes the carbide insert to rapidly heat and cool, leading to thermal cracks (comb cracks). You have two choices: run completely dry (not recommended for stainless due to BUE) or flood it consistently. For drilling, check our coolant-through drills which apply this principle perfectly.

High-Pressure Coolant (HPC)

Standard flood coolant often vaporizes before it reaches the cutting zone due to the ‘vapor barrier’ formed by extreme heat. High-Pressure Coolant (70 bar / 1000 psi) blasts through this barrier, cooling the edge and, crucially, hydraulically breaking the stringy chips that plague stainless turning.

Tip 4: Chip Control and Geometry

Long, stringy chips are dangerous to the operator and can scratch the workpiece surface. This is a common issue in grooving operations as well.

Positive Rake Angles

Select inserts with a highly positive rake angle (e.g., chipbreakers designated for ‘M’ or ‘S’ ISO groups). A positive angle reduces cutting resistance and heat generation. Avoid flat, negative geometries intended for hardened steel or cast iron, as they will push the material rather than cut it.

Tip 5: Rigidity and Center Height

Vibration is a catalyst for work hardening. When a tool chatters, it is essentially hammering the workpiece surface, hardening it instantly.

Check Center Height

If the tool tip is slightly below center, the material rolls over the top of the insert rather than being cut. If it is above center, the relief angle is reduced, causing rubbing. For stainless steel, the tool tip must be within **±0.1mm** of the centerline to ensure proper shearing action.

Recommended Parameters: 300 vs 400 Series

| Material Group | Grade (ISO) | Vc (Surface Speed) | Fn (Feed Rate) |

| 304 / 304L (Austenitic) | M10 – M20 (PVD) | 140 – 200 m/min | 0.15 – 0.35 mm/rev |

| 316 / 316L (Austenitic) | M20 – M30 (PVD) | 120 – 170 m/min | 0.15 – 0.30 mm/rev |

| 416 / 420 (Martensitic) | P10 – P20 (CVD) | 200 – 280 m/min | 0.20 – 0.50 mm/rev |

| Duplex (2205) | M30 (PVD) | 90 – 130 m/min | 0.12 – 0.25 mm/rev |

Troubleshooting: Identifying the Enemy

1. Built-Up Edge (BUE)

Symptom:Material welds to the insert tip, altering geometry and causing poor surface finish.

Fix: Increase Vc (cutting speed) to increase heat slightly (softening the flow zone), or use a PVD grade with a smoother top coating.

2. Notch Wear (Depth of Cut Notch)

Symptom: A localized groove or notch forms on the cutting edge at the exact depth of the cut.

Fix: This is caused by the work-hardened skin of the raw material (or previous pass). Use a tougher grade, vary the depth of cut between passes (ramping), or choose an insert with a larger lead angle.

FAQ: Stainless Steel Turning Solutions

1. Why do my inserts chip instantly in stainless?

Instant chipping usually indicates instability. Check your center height (it might be too high), minimize tool overhang, and ensure the workpiece is clamped securely. Vibration creates impact loads that brittle carbide cannot withstand.

2. Should I cut dry or wet?

For stainless steel, Wet (Flood Coolant) is almost always preferred to control heat and evacuate chips. However, if you are using Ceramic or CBN inserts (rare for 300 series), dry cutting is required to prevent thermal shock.

3. Can I use the same grade for 304 and 316?

Generally, yes. However, 316 contains Molybdenum, making it more abrasive and corrosion-resistant than 304. For 316, you may need to reduce cutting speeds by 10-15% compared to 304 to maintain tool life.

4. How do I get a mirror finish on stainless?

Use a Cermet grade insert for the final finishing pass. Cermet resists chemical wear and BUE better than standard carbide at high speeds/low feeds. Ensure you use a high positive rake geometry. For threading finishes, check our threading tools guide.

5. What is ‘Dwell’ and why is it bad?

Dwelling is when the tool stays in contact with the material without feeding (e.g., at the bottom of a groove). In stainless, this friction instantly work-hardens the surface, causing failure when you try to retract or cut again. Never dwell in stainless.

6. Are wiper inserts good for stainless?

Yes, Wiper inserts allow you to double the feed rate while maintaining the same surface finish. This is excellent for stainless because the higher feed rate ensures you are cutting efficiently and reducing the time the tool spends in the cut, thus lowering heat accumulation.

Conclusion: Mastering the Material

Turning stainless steel doesn’t have to be a battle against tool life. By understanding the mechanism of work hardening and selecting the correct PVD-coated tools with positive geometries, you can transform a difficult job into a profitable one.

Ready to upgrade your stainless steel operations? Browse our range of industrial turning inserts or contact our technical team for a specific grade recommendation.